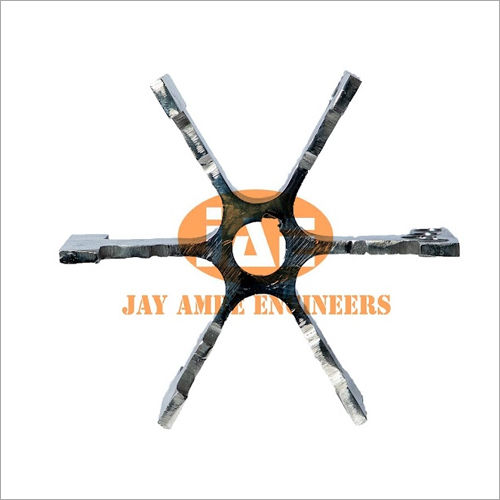

3HP Pulverizer 6 Cutter MS

Price 500 INR/ Piece

MOQ : 100 Pieces

3HP Pulverizer 6 Cutter MS Specification

- Features

- High performance

- Size

- Standard

- Product Type

- Machine Parts

- Material

- Steel

- Surface Treatment

- Painted

- Color

- Black, Silver, Blue

- Warranty

- Yes

3HP Pulverizer 6 Cutter MS Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 500 Pieces Per Week

- Delivery Time

- 7 Days

About 3HP Pulverizer 6 Cutter MS

Pulverizer 6 Cutter MS is a robust pulverizing machine designed for heavy-duty grinding and pulverization of various materials. It features six sharp cutters or blades made of MS (mild steel) that efficiently crush and reduce materials into fine powders. This machine is commonly used in industries such as food processing, chemical, and agricultural for high-volume material processing.

Frequently Asked Questions (FAQ) :

Q: What is the purpose of a Pulverizer 6 Cutter MS?

A: The primary purpose of a Pulverizer 6 Cutter MS is to grind, crush, and pulverize materials into fine powders. It is used in various industries for large-scale processing and pulverization of materials like grains, spices, herbs, chemicals, plastics, and more.

Q: How does a Pulverizer 6 Cutter MS work?

A: A Pulverizer 6 Cutter MS operates by feeding the material into the grinding chamber where the rotating cutters or blades made of MS (mild steel) efficiently cut and pulverize the material. The high-speed rotation of the blades generates impact and shearing forces that reduce the material into fine particles.

Q: What types of materials can be processed using a Pulverizer 6 Cutter MS?

A: A Pulverizer 6 Cutter MS can process a wide range of materials, including grains, spices, herbs, seeds, plastics, resins, and other solid materials. It is particularly effective for materials that require efficient grinding and pulverization into fine powders.

Q: What are the advantages of using a Pulverizer 6 Cutter MS?

A: Using a Pulverizer 6 Cutter MS offers several advantages. It is designed for heavy-duty operations, capable of processing large volumes of materials efficiently. The six sharp cutters made of MS (mild steel) ensure effective grinding and pulverization. The machine is sturdy, durable, and built to withstand high-intensity operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pulverizer Spare Parts Category

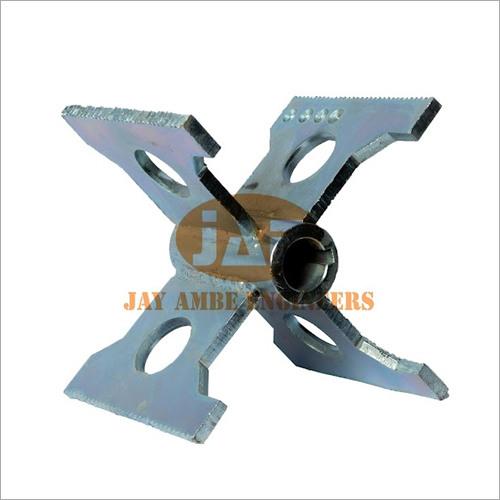

4 Cutter Aluminium Pulverizer Spare Parts

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Steel

Surface Treatment : Painted

Color : Black, Silver, Blue

Product Type : Machine Parts

SS Cutter Blade Pulverizer Spare Parts

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Steel

Surface Treatment : Painted

Color : Black, Silver, Blue

Product Type : Machine Parts

Pulverizer 4 Cutter MS Spare Parts

Price 500 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Steel

Surface Treatment : Painted

Color : Black, Silver, Blue

Product Type : Machine Parts

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free